The key Uncooked materials for biological manufacturing really should be gathered from sources demonstrated for being totally free from contamination and they must be handled in such a way as to minimize contamination plus the opportunities for just about any type of microbial contaminant to multiply in them.

Sartorius supplies a committed consumer manager to coordinate biosafety testing and to liaise with commercial enhancement teams. Our staff will tutorial you thru the process and make sure achievement.

four. Possibility Evaluation: Conducting threat assessments to determine potential resources of contamination and utilizing ideal mitigation approaches is essential.

The components needs to be effectively sterilized applying suited sterilization methods that won't influence the quality, texture as well as Organic activity inherent in them. Raw materials that are not sterilized and the ones that are to generally be processed more just after sterilization ought to be taken care of aseptically to stop doable contamination possibly through storage or handling.

Our group is on the market to debate the very best USP seventy one sterility testing method to your products. Make contact with us to talk about your sterility testing requires.

This doc discusses in-procedure good quality Command (IPQC) checks for parenteral products. It describes quite a few crucial IPQC checks like drug material assays, clarity testing to detect particulate matter using a variety of methods, leakage testing of ampoules making use of dye bath or spark checks, sterility testing making use of membrane website filtration or direct inoculation methods, and endotoxin/pyrogen testing.

The visual inspection is finished by holding the ampule by its neck towards extremely illuminated screens. White screens for the detection of black particle and black screens with the detection of white particles to detect significant particles it might be required to invert container but care has to be exercised to avoid air bubble. The instrumental methods are based on principles of sunshine scattering, mild absorption, electrical resistance as in coulter counter. A method which utilizes a movie impression projection could detects a moving particle without the need of destruction of merchandise unit.

In Immediate Inoculation, the solution is included to lifestyle media to check for microorganism Restoration. Suitability testing is required For each new sample, formulation transform, or modified testing procedure.

Navigating the regulatory pathway to a primary batch good deal launch is complicated. It takes a concentrated workforce of gurus to oversee testing and characterization activities.

The validation method for applying RMM necessitates you to definitely demonstrate that the new method is appropriate for your supposed purpose by demonstrating its specificity, limit of detection, robustness, precision, and reproducibility.

This guidebook presents a detailed overview of The 2 Main sterility testing methods outlined in USP seventy one:

A dairy product producer needed to assess the caliber of milk on arrival to help make fast choices. Listeria monocytogenes is The real key contaminant of concern in raw milk.

On the earth of pharmaceutical manufacturing, sterility testing is An important regulatory approach to make certain that your products are no cost from microbial contamination. As opposed with compendial testing methods, speedy microbiology methods (RMM) present sizeable benefits in pace and precision.

The dairy market place is beneath a strong transformation that brings about innovation and reshape the quality mentality. On the flip side Plant Based mostly is also strongly influencing the industry with a completely distinct new obstacle, with considerably more complicated settings and emerging risks.

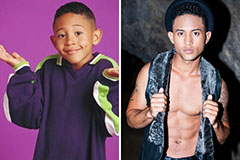

Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now!